Dynamic Braking Solutions

Rugged, compact resistor systems to safely dissipate regenerative energy in motor-driven systems.

Type

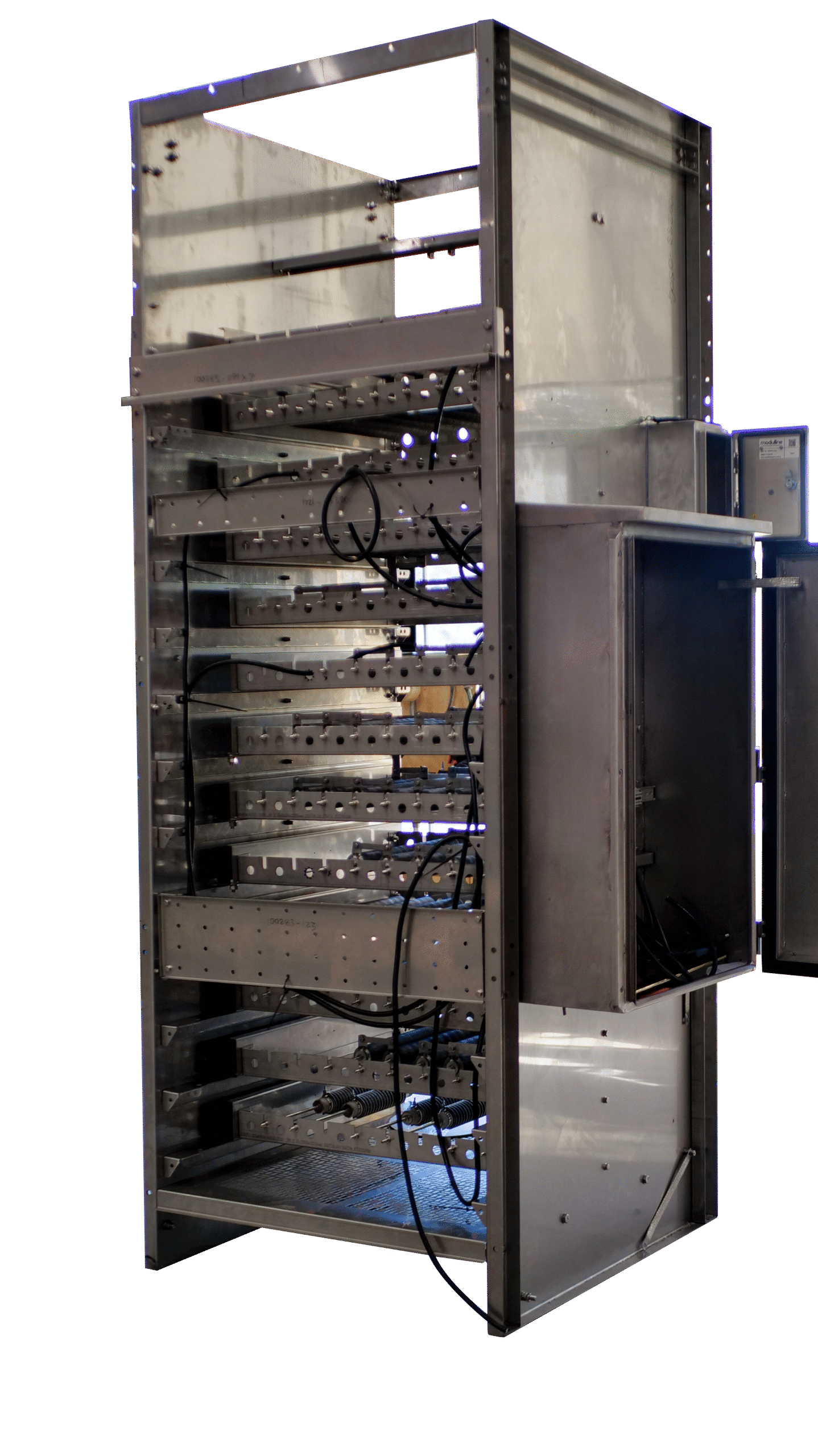

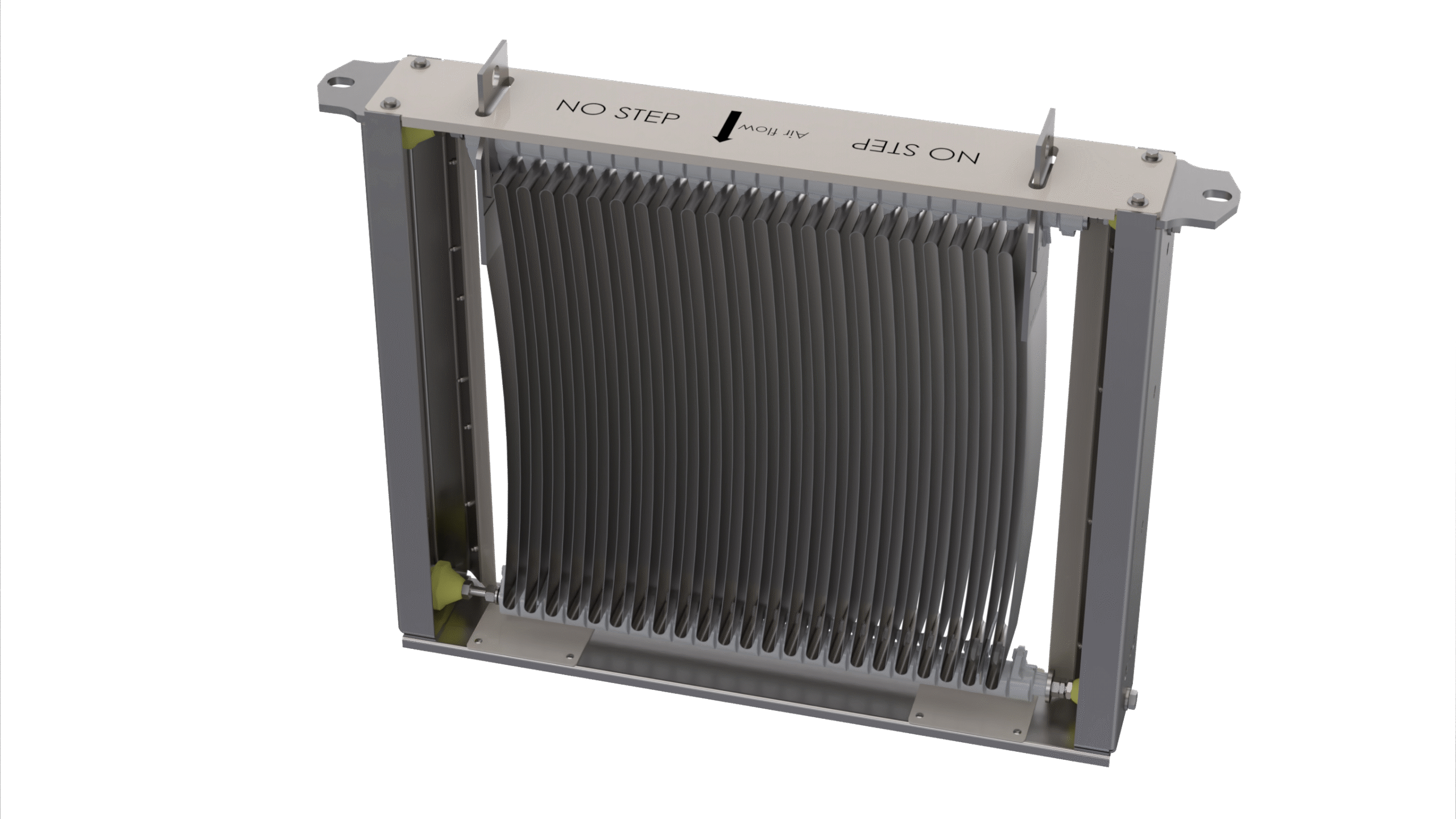

Model: Dynamic Braking Resistors (DBR)

Model Range: Fortress DBR Series

Resistance Range: Engineered to spec (1Ω–100Ω typical)

Voltage Rating: Up to 1,000V DC

Power: Up to 500kW

Ingress Protection: IP20 / IP23

Mounting: Open frame, enclosed cabinet or skid-mounted

Materials: Galvanised or stainless steel enclosure

Model: Transit Resistors

Type: Transit Resistors

Brand: Telema

Model: Custom

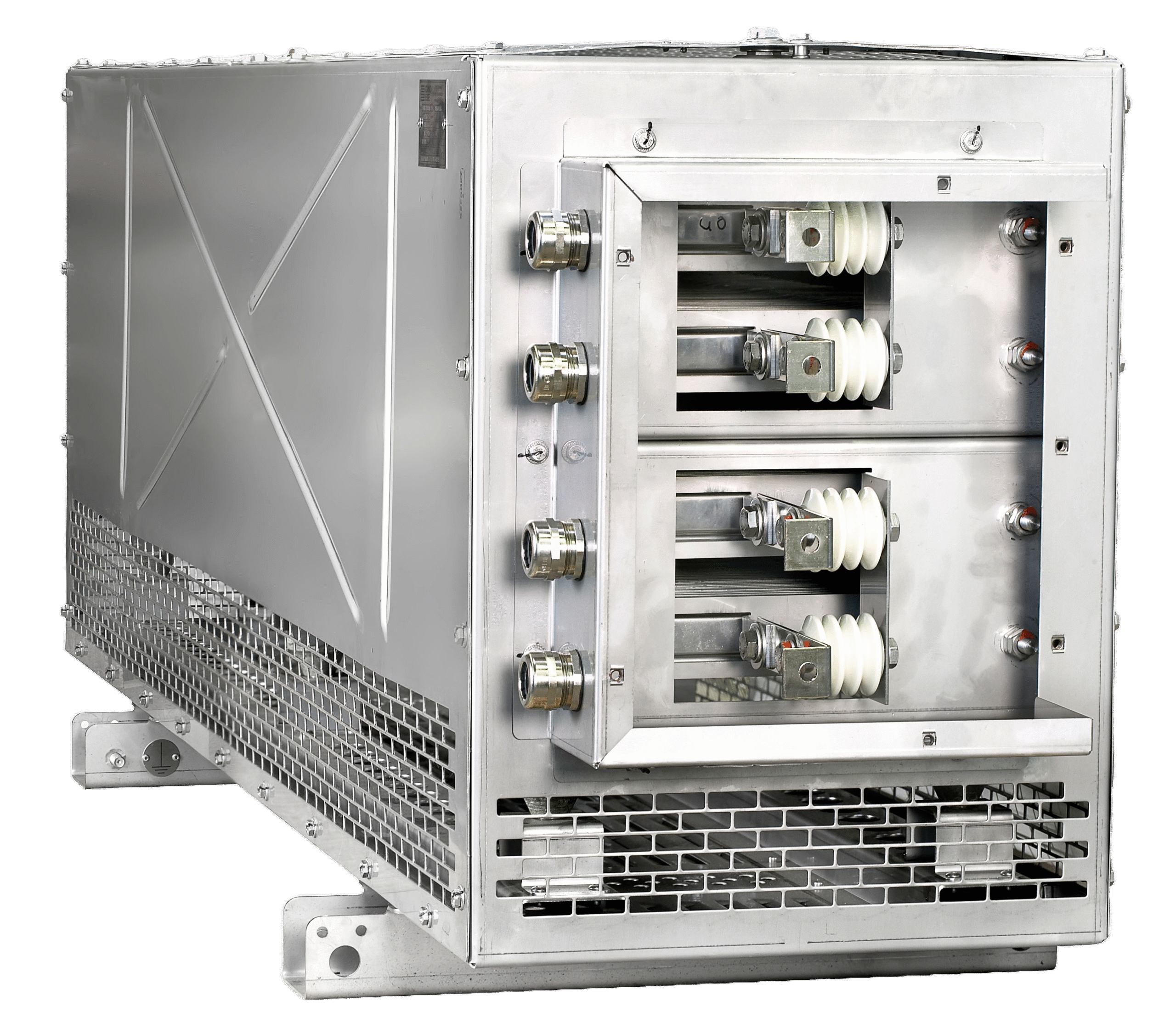

Model: Mining Truck (Grid Box) Resistors

Type: Mining Truck (Grid Box) Resistors

Brand: Mosebach (USA) / Gino-ESE (Germany)

Model: Komatsu / Hitachi / Liebherr

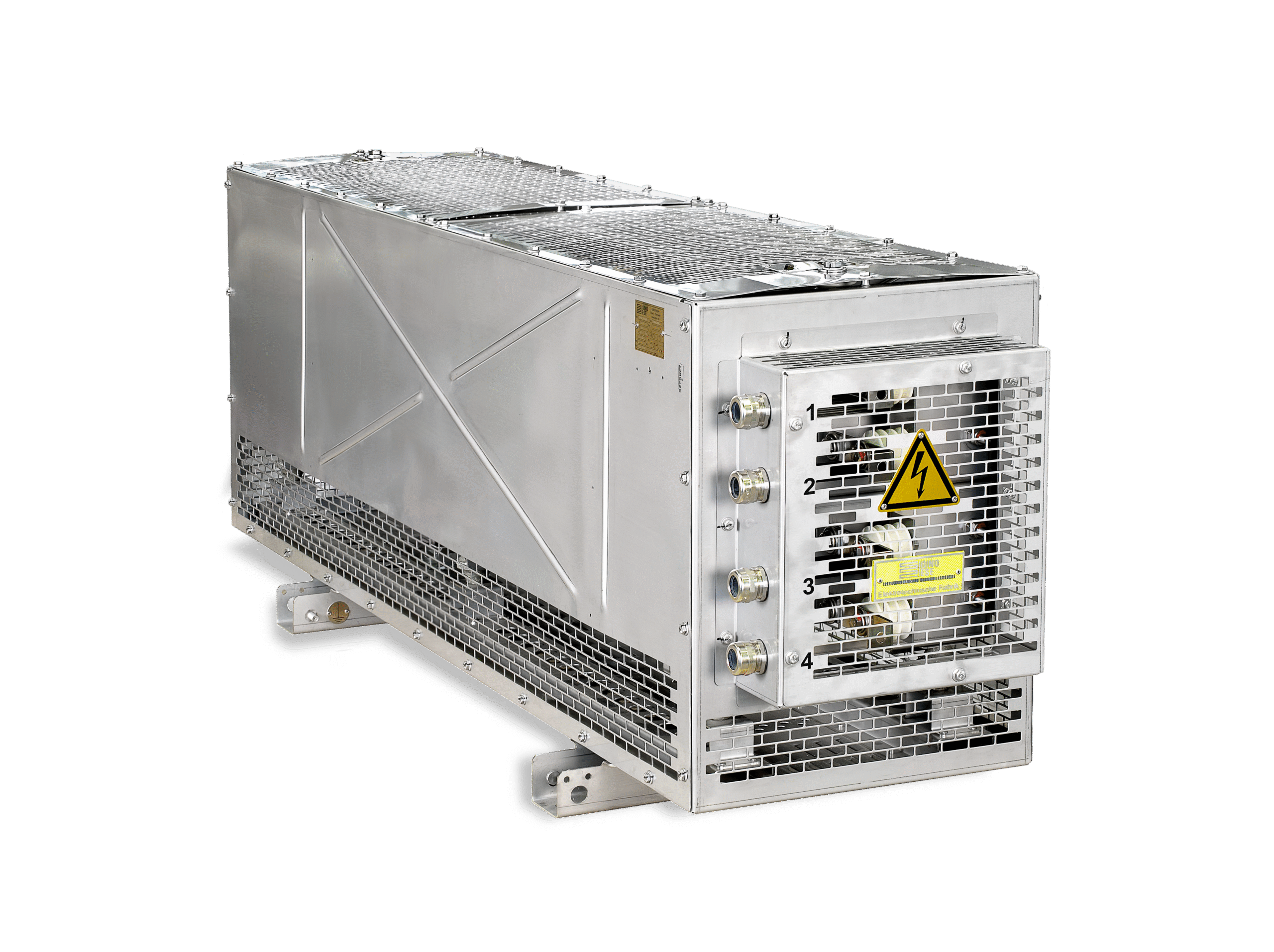

Model: EV Water Cooled Resistors

Type: Water Cooled Resistors

Brand: Cressall (United Kingdom)

Model: EV2

Power Rating: Up to 25kW per module (coolant and flow-dependent)

Configuration: Stackable up to 5 modules

Coolant Types: De-ionised Water, 20% Glycol, 50% Glycol

Operating Temperature: -30°C to +50°C

Minimum Flow Rates: Application dependent

Specification

Model: Dynamic Braking Resistors (DBR)

Model Range: Fortress DBR Series

Resistance Range: Engineered to spec (1Ω–100Ω typical)

Voltage Rating: Up to 1,000V DC

Power: Up to 500kW

Ingress Protection: IP20 / IP23

Mounting: Open frame, enclosed cabinet or skid-mounted

Materials: Galvanised or stainless steel enclosure

Model: Transit Resistors

Type: Transit Resistors

Brand: Telema

Model: Custom

Model: Mining Truck (Grid Box) Resistors

Type: Mining Truck (Grid Box) Resistors

Brand: Mosebach (USA) / Gino-ESE (Germany)

Model: Komatsu / Hitachi / Liebherr

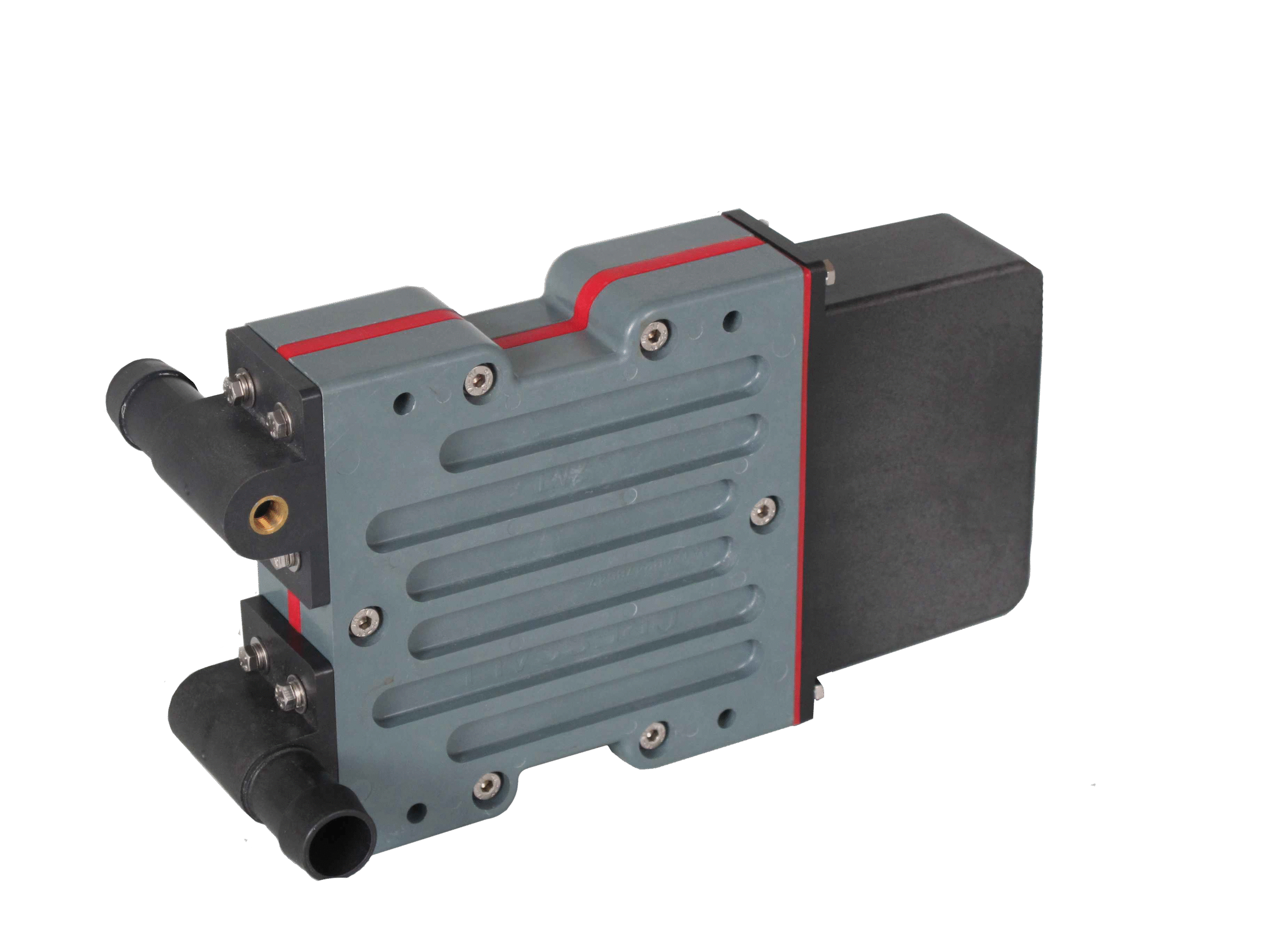

Model: EV Water Cooled Resistors

Type: Water Cooled Resistors

Brand: Cressall (United Kingdom)

Model: EV2

Power Rating: Up to 25kW per module (coolant and flow-dependent)

Configuration: Stackable up to 5 modules

Coolant Types: De-ionised Water, 20% Glycol, 50% Glycol

Operating Temperature: -30°C to +50°C

Minimum Flow Rates: Application dependent

Details

Use Case: Motor Braking and Overvoltage Suppression

Dynamic braking resistors are used in motor-driven systems to absorb excess energy released during deceleration. Common across cranes, hoists, conveyors and HVAC systems, DBRs help prevent damaging overvoltage conditions.

Standard DBR Units

Fortress offers a pre-engineered DBR range that meets most common VFD resistance and power requirements. These are available with short lead times and can be deployed in a range of industrial environments.

Bespoke DBR Options

Custom designs are available for clients requiring specific enclosure shapes, IP ratings or mounting formats. Fortress DBRs are available for marine, crane, HVAC and rail applications and can be tailored in collaboration with our global partner Telema.

We’re here to answer all your questions

Got questions? We’ve got answers! Below are some of the most common inquiries about our products and services. If you don’t find what you’re looking for, feel free to reach out to our team—we’re happy to help!

Fortress has designed a range of resistances and power ratings that satisfy most VFD minimum and maximum requirements. This reduces the need for custom designs and allows for faster delivery.

Yes – Fortress DBRs are compatible with all major VFD brands and can be tuned to match.

Stocked models can ship within 1–2 days. Built-to-order standard units typically ship in 2–4 weeks. High power DBRs may require 4–8 weeks.

Fan cooling is generally not required. It is only considered when space constraints limit the available footprint.

The minimum information required includes motor power, drive minimum resistance, duty cycle (on/off time in seconds), and load profile.