About Us

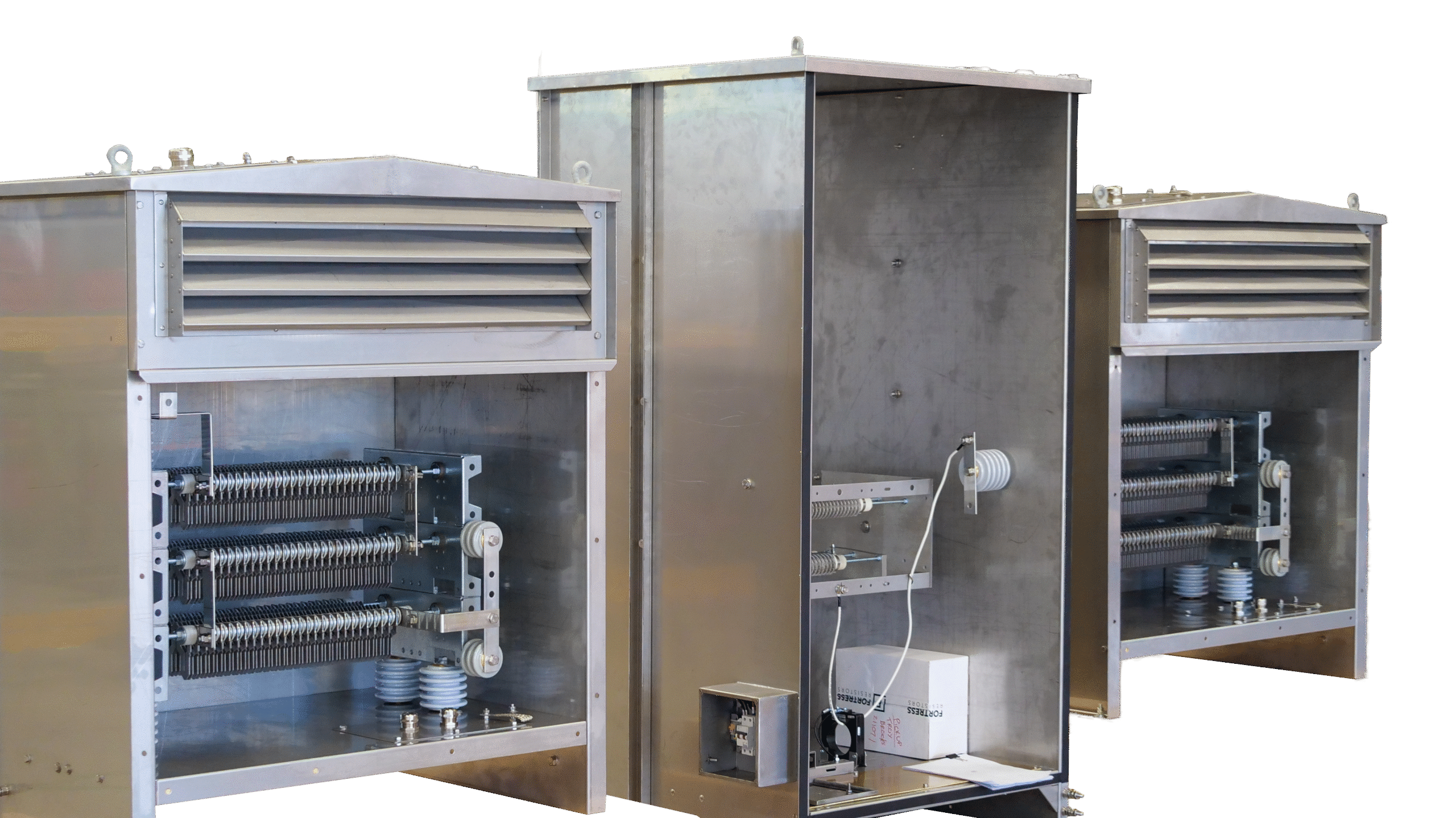

Fortress Systems delivers high-quality, reliable, and innovative power resistor solutions.

The origins of Fortress Systems date back to the foundation of the Electroswitch brand in 1976 in Newcastle, NSW. The Electroswitch brand was created by four pioneers of the Australian electrical industry who had previously worked at Crompton Parkinson before they ceased local manufacturing in 1967. Electroswitch grew to become the leading Australian manufacturer of high-power resistors.

From 1980 Fortress Security Pty Ltd was a manufacturer of trapped key interlocking products owned by the UK listed Halma Group PLC. Halma also owned a resistor division which included the internationally recognised brands of Post Glover and Cressall. In 1990 Fortress Security began importing Post Glover Neutral Earthing Resistors for sale in Australia and New Zealand. The business grew and in 1994 Fortress Security purchased the Electroswitch business from Ampcontrol Group. The manufacturing operation was moved to Braeside in Victoria and combined into the Halma Group resistor division.

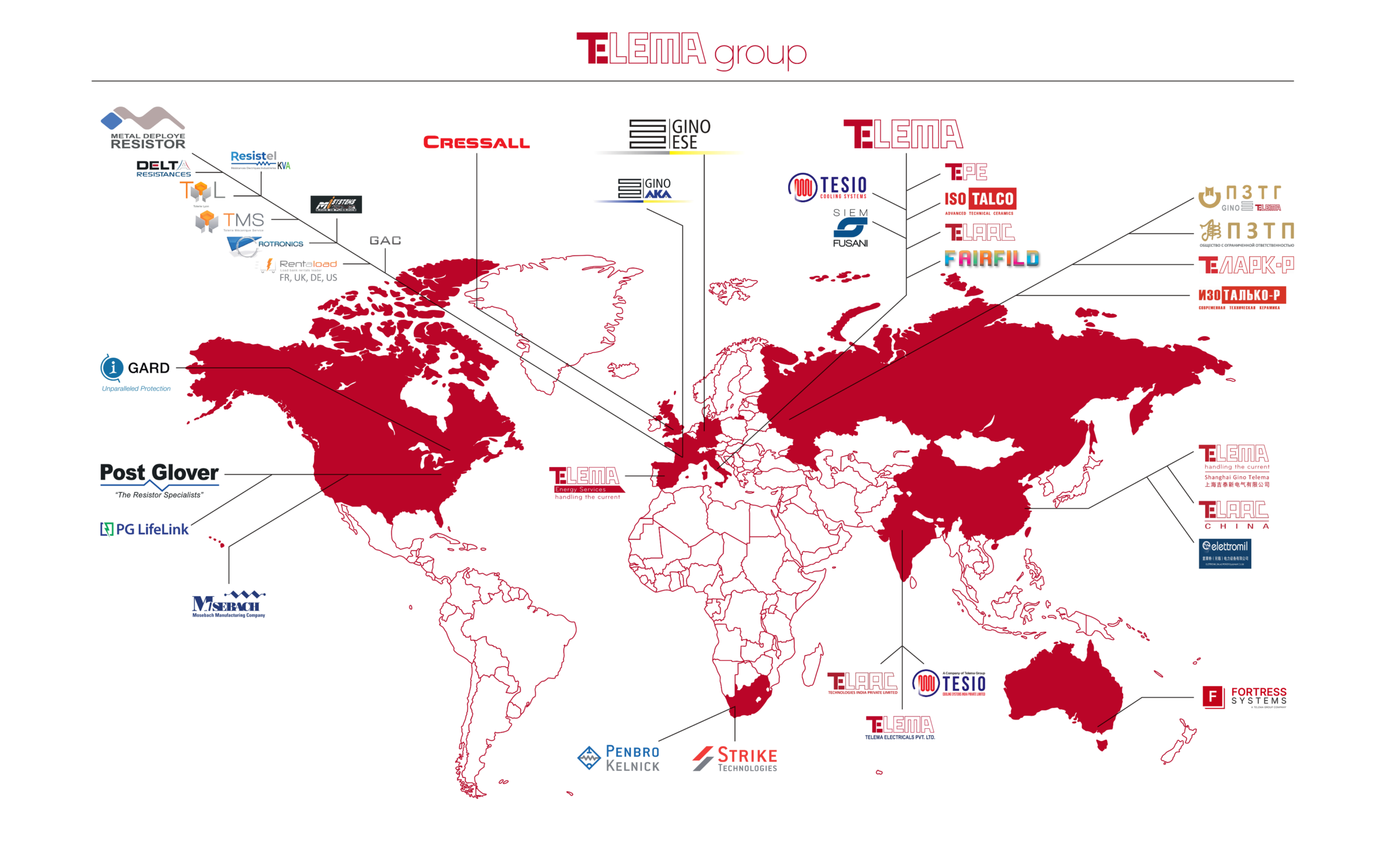

In 1995 Telema purchased the Halma Group resistor division, excluding Fortress Systems Pty Ltd. Telema S.p.A.was founded in 1975 in Milan, Italy with an initial focus in braking resistors used in the European transit market. Telema is now a global group with operations in Europe, North America, China, India, Australia, Russia, and South Africa, with over 2,500 employees globally.

In 1998 the company name was changed to Fortress Systems Pty Ltd to reflect the increased importance of the resistor business.

In February 2009 Fortress Systems was purchased by Telema, with a reporting line to Post Glover Resistors. At the same time, the interlock division of the company was separated out as Fortress Interlock and retained by the Halma Group PLC. Post Glover, the leading provider of power resistor products in North America, was founded in 1893.

Since 2009 Fortress Systems have invested in new manufacturing equipment to bring in house the majority of processes required to manufacture sheet metal electrical enclosures and power resistors.

Fortress Systems is now dedicated to the design, manufacture, supply and aftermarket support of:

- Neutral Earthing Solutions

- Motor Control Solutions

- Load Bank Solutions

- Filter Resistor Solutions

- Dynamic Braking Solutions

- Safety and Protection Solutions

Fortress Systems is committed to the on-time supplying of products and services which meet the requirements and specification, stated or implied, of its customers, while ensuring all products comply with all relevant Australian and international design standards required electrical standards and other legal obligations. Fortress Systems quality system is certified by DNV to ISO90021.

It is the responsibility of everyone within the company to ensure the quality of our products by following the policies and procedures detailed in the Quality Plan. Fortress Systems is committed to supplying products and services which meet the requirements and specification stated or implied, by its customers while ensuring all products comply with required electrical standards and other legal obligations. This is achieved through the operation of a Quality Management System to a standard which satisfies ISO9001 and ISO45001.

The company is committed to a process of continuous improvement through the use of the Quality Management System.

We do this to:

- Enhance customer satisfaction;

- Improve financial performance;

- Increase productivity; and

- Encourage innovation.

This also ensures the ongoing development of:

- Employee expertise

- Product performance

- Engineering capability

- Production methods and

- Business systems in a cost effective and efficient manner.

A key objective of continuous improvement is to ensure a profitable and sustainable company that provides stable employment opportunities.

Managers within Fortress Systems must ensure that people under their supervision are trained in, know, and understand all aspects of their roles as well as the quality policy and procedures. The Quality Management System covers the processes of definition, development and the review of the knowledge and skills required for each aspect of the business.

Fortress Systems is committed to providing and maintaining, so far as is reasonably practicable, a working environment, including off-site activity, for employees, contractors, customers and visitors, that is safe and without risk to health (physical or mental).

Fortress Systems OH&S system is certified by DNV to ISO45001.

Our overall objective is to prevent workplace illness and injury. Fortress Systems is committed to continual improvement of the OH&S Management System and OHS performance through its measurement, communication and monitoring activities.

In order to meet safety objectives Fortress Systems has established an OH&S Management System in compliance with the ISO45001 Standard.

We will strive to achieve our overall objective, on an ongoing basis, by:

- Complying with all relevant OH&S legislation, applicable industry standards, customer requirements, OHS Regulations, codes of practice/compliance codes as well as other requirements related to the OHS hazards as a result of our operations.

- Establishing, reviewing and communicating Fortress Resistors Systems’s safety objectives and targets that are measurable to all levels in the organisation. The objectives and targets are monitored on an ongoing basis and reviewed during the management review meetings.

- Identifying and reducing the risks of all types of work activities that have the potential to produce personal injury or occupational illness. Hence, all staff and contractors are encouraged to report all workplace hazards, incidents, near-misses and accidents to the relevant OH&S representative.

- Focusing on ongoing improvement in the areas of safety education, accident prevention, hazard management, injury prevention, incident and near-miss reporting, rehabilitation and health preservation.

- Providing and maintaining plant and systems of work in a safe manner.

- Ensuring appropriate information, instruction, supervision, communication, consultation, induction and training are provided to all staff and contractors prior to commencement of work, and ensuring all employees and contractors are aware of these resources and participate proactively in the above.

Technology, Innovation, Performance and Flexibility are the outcomes our customers want and expect us to deliver.

High reliability and quality are the goals we share with our customers.

Since its foundation TELEMA has always dedicated all its resources, personnel, investment, research & development – to the technical improvement of its products of which the TELEMA group is the world largest specialist manufacturer: Power Electric Resistors for railways and industrial applications.

TELEMA S.p.A. designs and produces since 1975 Stainless Steel Power Resistors, addressed to the most various application areas, in its factory in Piacenza. The company started its activity mainly in Italy and at the end of 90’s, to meet the needs of the market, the company has extended its presence abroad, firstly in Europe (France, UK, Germany) and then worldwide (USA, Canada, China, India, Australia, Russia and South Africa) .Today the Telema Group is the world leader for the Power Electric Resistors with more than 2000people, of which 160 in Telema Italy, and a revenue of 400 million Euros.This growth has been achieved thanks to the diversification of the product portfolio that in recent years it has been expanded with the offer of contactors, disconnectors and protection relays for the railway market, in addition to the cooling fans for our applications in forced ventilation; the cooling fans.

TELEMA is in the list of the “best suppliers” for the most important worldwide builder of railway vehicle, from trams to metros, from high-speed trains to high-speed trains.

Our main strengths are:

- Focus on Innovation

- Flexibility and creativity to achieve the best solution for customers, from small to large global player

- Entrepreneurial approach with the consequent passion and determination that has always driven us to invest for growth

- Control of all internal processes with metrics and performance analysis

Our claim is HANDLING THE CURRENT because, thanks to our wide range of products and solutions, we are able to assess and manage all the aspects related to the current.

The origins of Fortress Systems date back to the foundation of the Electroswitch brand in 1976 in Newcastle, NSW. The Electroswitch brand was created by four pioneers of the Australian electrical industry who had previously worked at Crompton Parkinson before they ceased local manufacturing in 1967. Electroswitch grew to become the leading Australian manufacturer of high-power resistors.

From 1980 Fortress Security Pty Ltd was a manufacturer of trapped key interlocking products owned by the UK listed Halma Group PLC. Halma also owned a resistor division which included the internationally recognised brands of Post Glover and Cressall. In 1990 Fortress Security began importing Post Glover Neutral Earthing Resistors for sale in Australia and New Zealand. The business grew and in 1994 Fortress Security purchased the Electroswitch business from Ampcontrol Group. The manufacturing operation was moved to Braeside in Victoria and combined into the Halma Group resistor division.

In 1995 Telema purchased the Halma Group resistor division, excluding Fortress Systems Pty Ltd. Telema S.p.A.was founded in 1975 in Milan, Italy with an initial focus in braking resistors used in the European transit market. Telema is now a global group with operations in Europe, North America, China, India, Australia, Russia, and South Africa, with over 2,500 employees globally.

In 1998 the company name was changed to Fortress Systems Pty Ltd to reflect the increased importance of the resistor business.

In February 2009 Fortress Systems was purchased by Telema, with a reporting line to Post Glover Resistors. At the same time, the interlock division of the company was separated out as Fortress Interlock and retained by the Halma Group PLC. Post Glover, the leading provider of power resistor products in North America, was founded in 1893.

Since 2009 Fortress Systems have invested in new manufacturing equipment to bring in house the majority of processes required to manufacture sheet metal electrical enclosures and power resistors.

Fortress Systems is now dedicated to the design, manufacture, supply and aftermarket support of:

- Neutral Earthing Solutions

- Motor Control Solutions

- Load Bank Solutions

- Filter Resistor Solutions

- Dynamic Braking Solutions

- Safety and Protection Solutions

Fortress Systems is committed to the on-time supplying of products and services which meet the requirements and specification, stated or implied, of its customers, while ensuring all products comply with all relevant Australian and international design standards required electrical standards and other legal obligations. Fortress Systems quality system is certified by DNV to ISO90021.

It is the responsibility of everyone within the company to ensure the quality of our products by following the policies and procedures detailed in the Quality Plan. Fortress Systems is committed to supplying products and services which meet the requirements and specification stated or implied, by its customers while ensuring all products comply with required electrical standards and other legal obligations. This is achieved through the operation of a Quality Management System to a standard which satisfies ISO9001 and ISO45001.

The company is committed to a process of continuous improvement through the use of the Quality Management System.

We do this to:

- Enhance customer satisfaction;

- Improve financial performance;

- Increase productivity; and

- Encourage innovation.

This also ensures the ongoing development of:

- Employee expertise

- Product performance

- Engineering capability

- Production methods and

- Business systems in a cost effective and efficient manner.

A key objective of continuous improvement is to ensure a profitable and sustainable company that provides stable employment opportunities.

Managers within Fortress Systems must ensure that people under their supervision are trained in, know, and understand all aspects of their roles as well as the quality policy and procedures. The Quality Management System covers the processes of definition, development and the review of the knowledge and skills required for each aspect of the business.

Fortress Systems is committed to providing and maintaining, so far as is reasonably practicable, a working environment, including off-site activity, for employees, contractors, customers and visitors, that is safe and without risk to health (physical or mental).

Fortress Systems OH&S system is certified by DNV to ISO45001.

Our overall objective is to prevent workplace illness and injury. Fortress Systems is committed to continual improvement of the OH&S Management System and OHS performance through its measurement, communication and monitoring activities.

In order to meet safety objectives Fortress Systems has established an OH&S Management System in compliance with the ISO45001 Standard.

We will strive to achieve our overall objective, on an ongoing basis, by:

- Complying with all relevant OH&S legislation, applicable industry standards, customer requirements, OHS Regulations, codes of practice/compliance codes as well as other requirements related to the OHS hazards as a result of our operations.

- Establishing, reviewing and communicating Fortress Resistors Systems’s safety objectives and targets that are measurable to all levels in the organisation. The objectives and targets are monitored on an ongoing basis and reviewed during the management review meetings.

- Identifying and reducing the risks of all types of work activities that have the potential to produce personal injury or occupational illness. Hence, all staff and contractors are encouraged to report all workplace hazards, incidents, near-misses and accidents to the relevant OH&S representative.

- Focusing on ongoing improvement in the areas of safety education, accident prevention, hazard management, injury prevention, incident and near-miss reporting, rehabilitation and health preservation.

- Providing and maintaining plant and systems of work in a safe manner.

- Ensuring appropriate information, instruction, supervision, communication, consultation, induction and training are provided to all staff and contractors prior to commencement of work, and ensuring all employees and contractors are aware of these resources and participate proactively in the above.

Technology, Innovation, Performance and Flexibility are the outcomes our customers want and expect us to deliver.

High reliability and quality are the goals we share with our customers.

Since its foundation TELEMA has always dedicated all its resources, personnel, investment, research & development – to the technical improvement of its products of which the TELEMA group is the world largest specialist manufacturer: Power Electric Resistors for railways and industrial applications.

TELEMA S.p.A. designs and produces since 1975 Stainless Steel Power Resistors, addressed to the most various application areas, in its factory in Piacenza. The company started its activity mainly in Italy and at the end of 90’s, to meet the needs of the market, the company has extended its presence abroad, firstly in Europe (France, UK, Germany) and then worldwide (USA, Canada, China, India, Australia, Russia and South Africa) .Today the Telema Group is the world leader for the Power Electric Resistors with more than 2000people, of which 160 in Telema Italy, and a revenue of 400 million Euros.This growth has been achieved thanks to the diversification of the product portfolio that in recent years it has been expanded with the offer of contactors, disconnectors and protection relays for the railway market, in addition to the cooling fans for our applications in forced ventilation; the cooling fans.

TELEMA is in the list of the “best suppliers” for the most important worldwide builder of railway vehicle, from trams to metros, from high-speed trains to high-speed trains.

Our main strengths are:

- Focus on Innovation

- Flexibility and creativity to achieve the best solution for customers, from small to large global player

- Entrepreneurial approach with the consequent passion and determination that has always driven us to invest for growth

- Control of all internal processes with metrics and performance analysis

Our claim is HANDLING THE CURRENT because, thanks to our wide range of products and solutions, we are able to assess and manage all the aspects related to the current.

Our Solutions

Neutral Earthing Solutions

NERs and NETs from Fortress Systems provide controlled grounding, limit fault currents, and support network safety and stability.

Read More

Filter Resistor Solutions

Our Filter Resistors reduce electrical noise and voltage fluctuations, helping maintain system stability and consistent performance.

Read More

Load Banks Solutions

Fortress Systems supplies load banks ranging from small portable loads for testing petrol generators to multi-megawatt high voltage loads for large diesel generators and gas turbines at up to 13.8kV.

Read More

Motor Control Solutions

Fortress offers both Fortress Motor Control Resistor Cabinets and Gino-AKA Liquid Cooled Starters that allow for the optimisation of electric motor performance by regulating current and enhancing cont

Read More

Dynamic Braking Solutions

Designed to safely dissipate excess energy, our DBRs support controlled braking in transit, mining truck, industrial and drive applications.

Read More

Safety and Protection Solutions

Through the supply of products from Telema sister companies I-Gard, Strike and Telarc, Fortress increases staff safety and equipment uptime.

Read More