Our Capabilities

Our Expertise

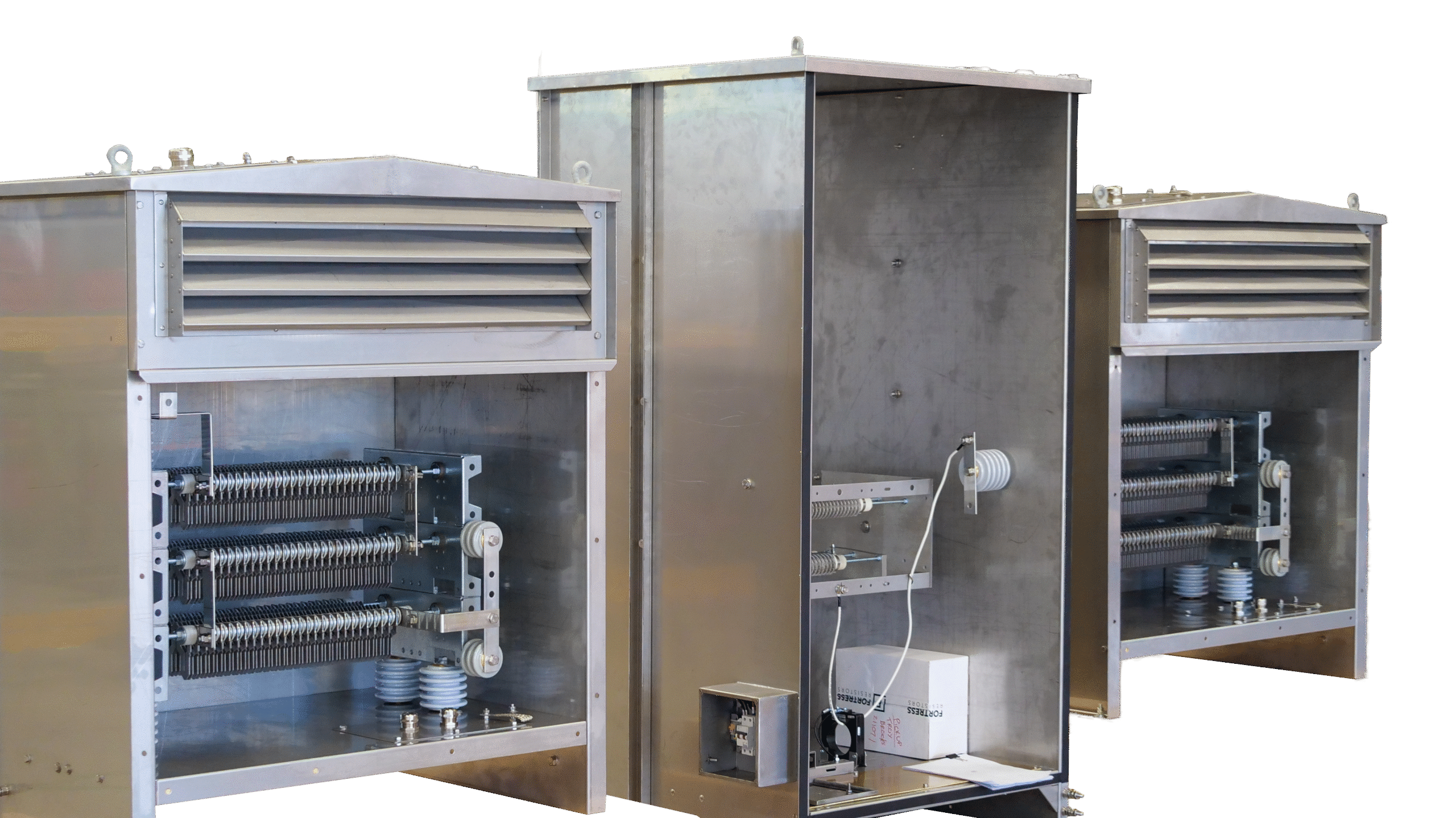

Fortress Systems are experts in the design and manufacture of products that utilise power resistor technologies.

Our sales, engineering team, and our production manufacturing teams are based in our Braeside, Melbourne facility.

Fortress’s engineering team uses the Autodesk suite of 3D design software and analysis tools, these allow Fortress to customise designs that meet a client’s exact requirements.

Through long term partnerships with structural engineers we are able to certify resistor design documents to Australian and New Zealand wind and seismic standards (AS/NZS 1170-2); Fortress can also design and certify enclosure designs to any international wind and seismic standard, as required.

As a Weld Australia member, on request, we can provide welding in compliance with the AS/NZS 1554 series of standards.

The Fortress Systems production team is made up of a locally trained team of operators who are experienced in sheet metal fabrication, mechanical assembly, and electrical installation work. We manufacture the majority of the resistor elements we use locally.

As a member of the Telema Group, we also have access to the resources of sister companies around the world and for specialist applications can utilise their resistor design skills when there is an advantage in doing so.

Local Facilities

Our in-house production equipment includes:

- Custom resistor element manufacturing equipment for the production of wire wound, edge wound and stamped grid resistor elements.

- A turret punch for the punching of sheet metal used in the fabrication of electrical enclosures.

- Press brakes for the folding of sheet metal and resistor elements.

- Welding equipment for TIG and MIG welding.

- The assembly and testing of blower assemblies for fan cooled resistors.

With our close ties to local industries, we can provide a wide variety of secondary processes to meet customer requirements, including:

- Surface finish options for protective or cosmetic purposes include powder coating, wet-spray painting, hot dipped galvanising, and brushed and natural finishes.

- Labelling solutions including engraved and paint-filled, or laser-etched stainless steel or aluminium labels, and custom vinyl adhesive labels.

Through long term relationships with key suppliers we are able to supply and install a large range of ancillary equipment alongside our resistors, including:

- NER / NGR Monitoring Systems

- Current transformers (CTs)

- Voltage transformers (VTs / PTs)

- High and low voltage circuit breakers

- High and low voltage contactors

- High voltage disconnectors, switch-disconnectors, and earth switches

- Outdoor bushings

- Outdoor post insulators

Our Solutions

Neutral Earthing Solutions

NERs and NETs from Fortress Systems provide controlled grounding, limit fault currents, and support network safety and stability.

Read More

Filter Resistor Solutions

Our Filter Resistors reduce electrical noise and voltage fluctuations, helping maintain system stability and consistent performance.

Read More

Load Banks Solutions

Fortress Systems supplies load banks ranging from small portable loads for testing petrol generators to multi-megawatt high voltage loads for large diesel generators and gas turbines at up to 13.8kV.

Read More

Motor Control Solutions

Fortress offers both Fortress Motor Control Resistor Cabinets and Gino-AKA Liquid Cooled Starters that allow for the optimisation of electric motor performance by regulating current and enhancing cont

Read More

Dynamic Braking Solutions

Designed to safely dissipate excess energy, our DBRs support controlled braking in transit, mining truck, industrial and drive applications.

Read More

Safety and Protection Solutions

Through the supply of products from Telema sister companies I-Gard, Strike and Telarc, Fortress increases staff safety and equipment uptime.

Read More