Motor Control Solutions

Advanced stepped-resistance solution engineered to control slip ring motor startup in high-torque industrial environments.

Type

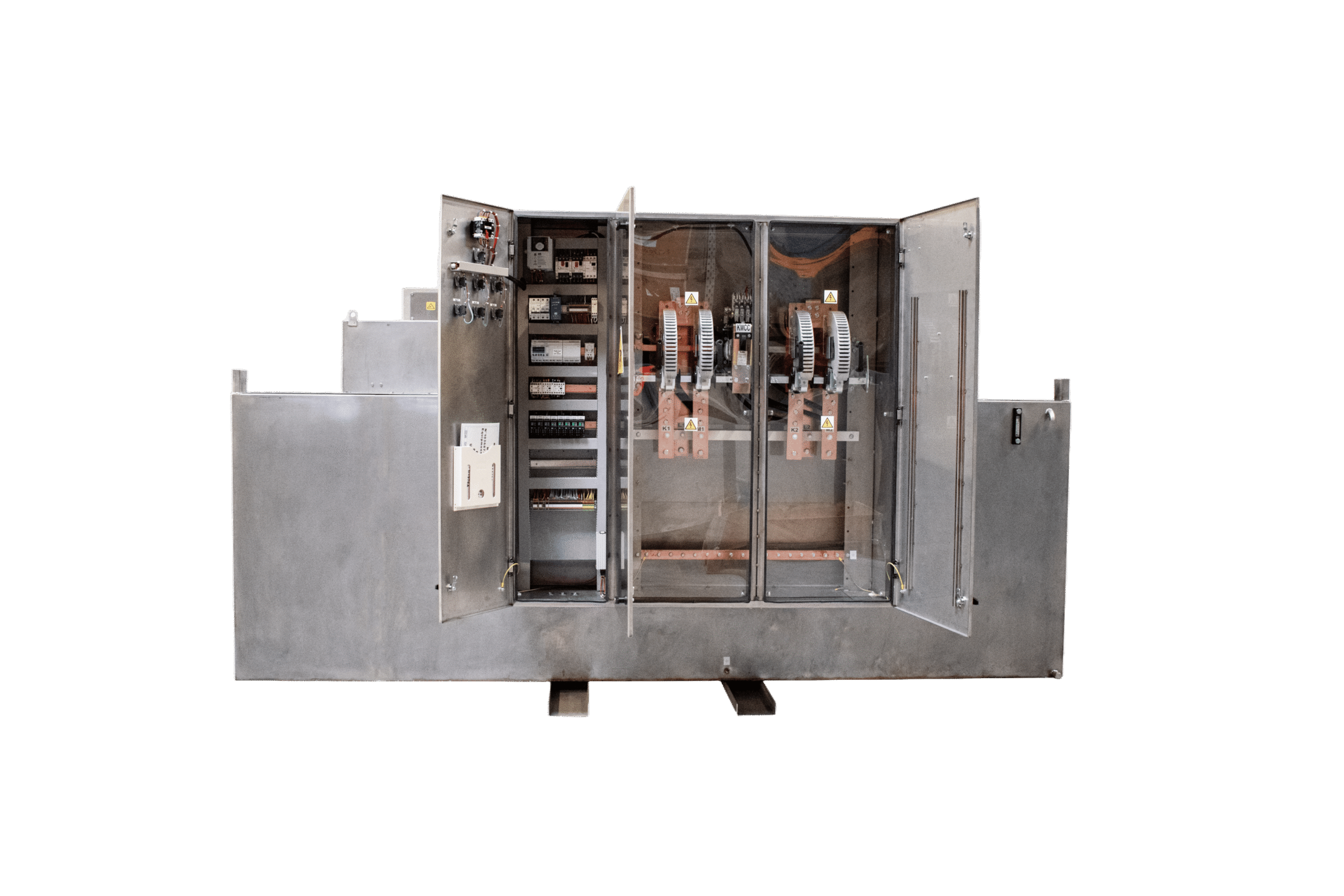

Model: Rotor Resistor Cabinets (RRC)

Type: Rotor Resistance Cabinet (RRC)

Brand: Fortress Systems

Model: Custom

Rotor Voltage: Up to 2kV

Rotor Current: Up to 800A

Torque Profile: Application-specific

Consecutive Starts: Engineered to requirement

Control Systems: Any (customer-specified)

Ingress Protection (Resistor Compartment): IP23, IP33, IP43

Ingress Protection (Controls Compartment): IP54, IP55, IP56

Materials: Mill galvanised steel (powder coated), 304 or 316 stainless steel

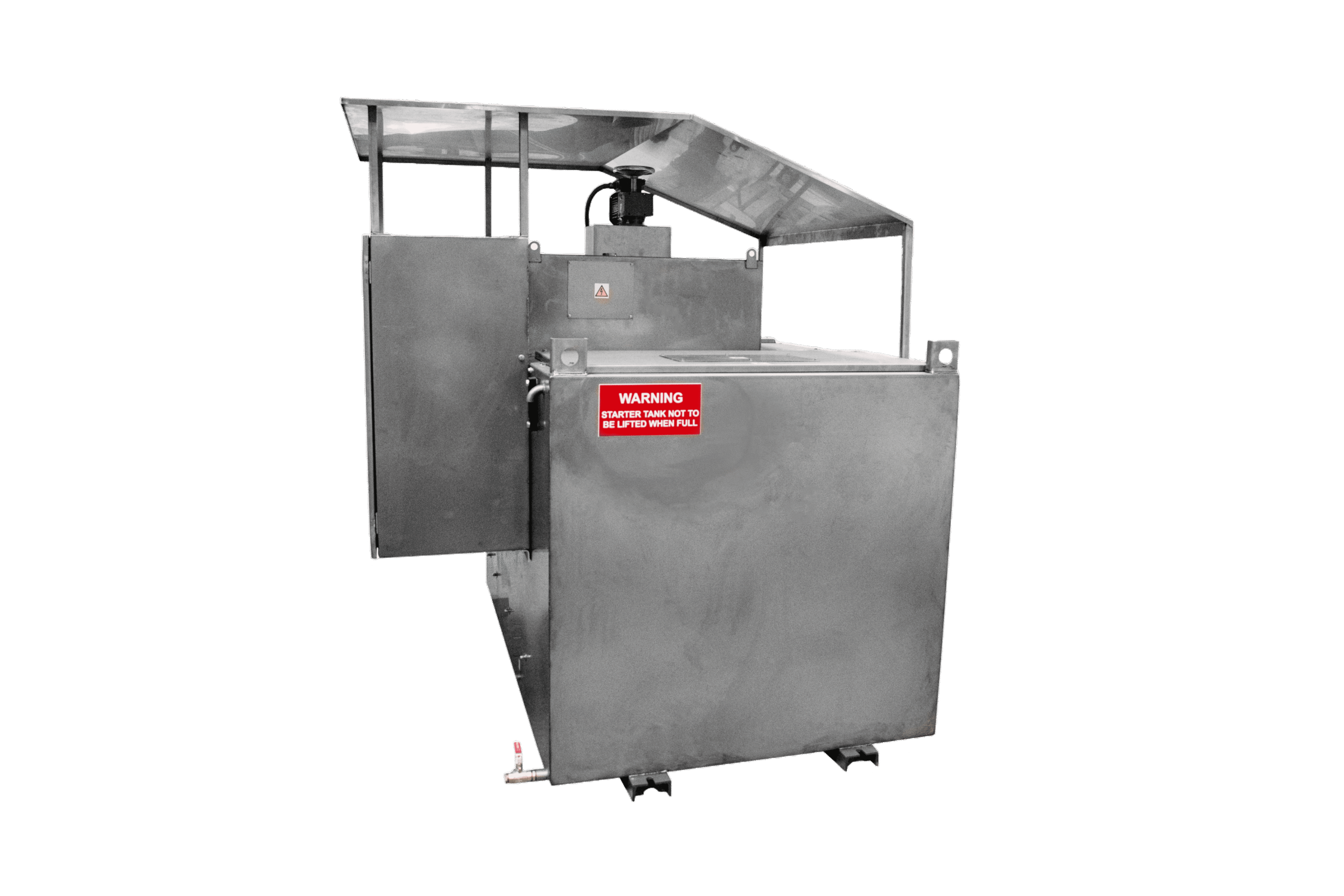

Model: Liquid Starter (Motor Starter System)

Type: Liquid Resistance Starter

Brand: Gino-AKA (France)

Models: AL, MAK, SKS, Compact

Motor Range: Up to 15MW

Voltage: 400V – 11kV (customisable)

Resistance Medium: Electrolytic solution

Electrode Travel: Vertical or horizontal

Electrode Material: Bronze alloy or stainless steel

Cooling: Natural or forced circulation

Construction: Enclosure and tank in mild steel or stainless steel

Control: Manual or automatic ramp sequencing

Model: Oil Cooled Starter (OCS)

Type: Oil Cooled Starter (OCS)

Brand: Gino-ESE (Germany)

Model: 3PA3

Motor Range: Up to 12.8MW

Voltage: Up to 5kV (customisable)

Resistance Medium: Mineral-based insulating oil (VDE 0370-2:2013-11, DIN EN 60296:2012-12, or IEC 60422:2013)

Construction: Mild steel or stainless steel enclosure and tank

Control: Cast iron resistor elements and power contactors

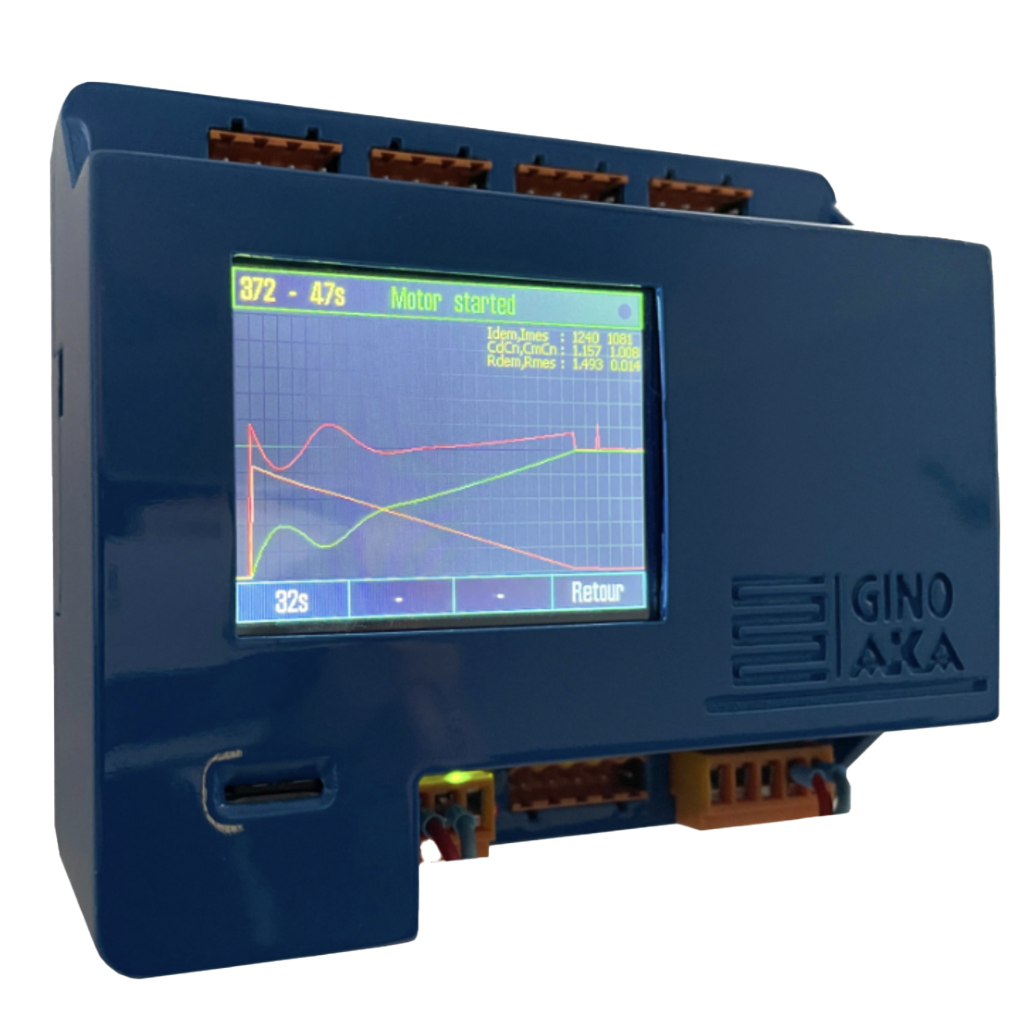

Model: Motor Monitoring (AKAMAS)

Type: Motor Monitoring System

Brand: Gino-AKA (France)

Model: AKAMAS 2.0

Connectivity: USB, Ethernet, Wi-Fi

Interface: Integrated touchscreen display

Data Logging: Custom Gino-AKA software (PC-based or remote access)

Specification

Model: Rotor Resistor Cabinets (RRC)

Type: Rotor Resistance Cabinet (RRC)

Brand: Fortress Systems

Model: Custom

Rotor Voltage: Up to 2kV

Rotor Current: Up to 800A

Torque Profile: Application-specific

Consecutive Starts: Engineered to requirement

Control Systems: Any (customer-specified)

Ingress Protection (Resistor Compartment): IP23, IP33, IP43

Ingress Protection (Controls Compartment): IP54, IP55, IP56

Materials: Mill galvanised steel (powder coated), 304 or 316 stainless steel

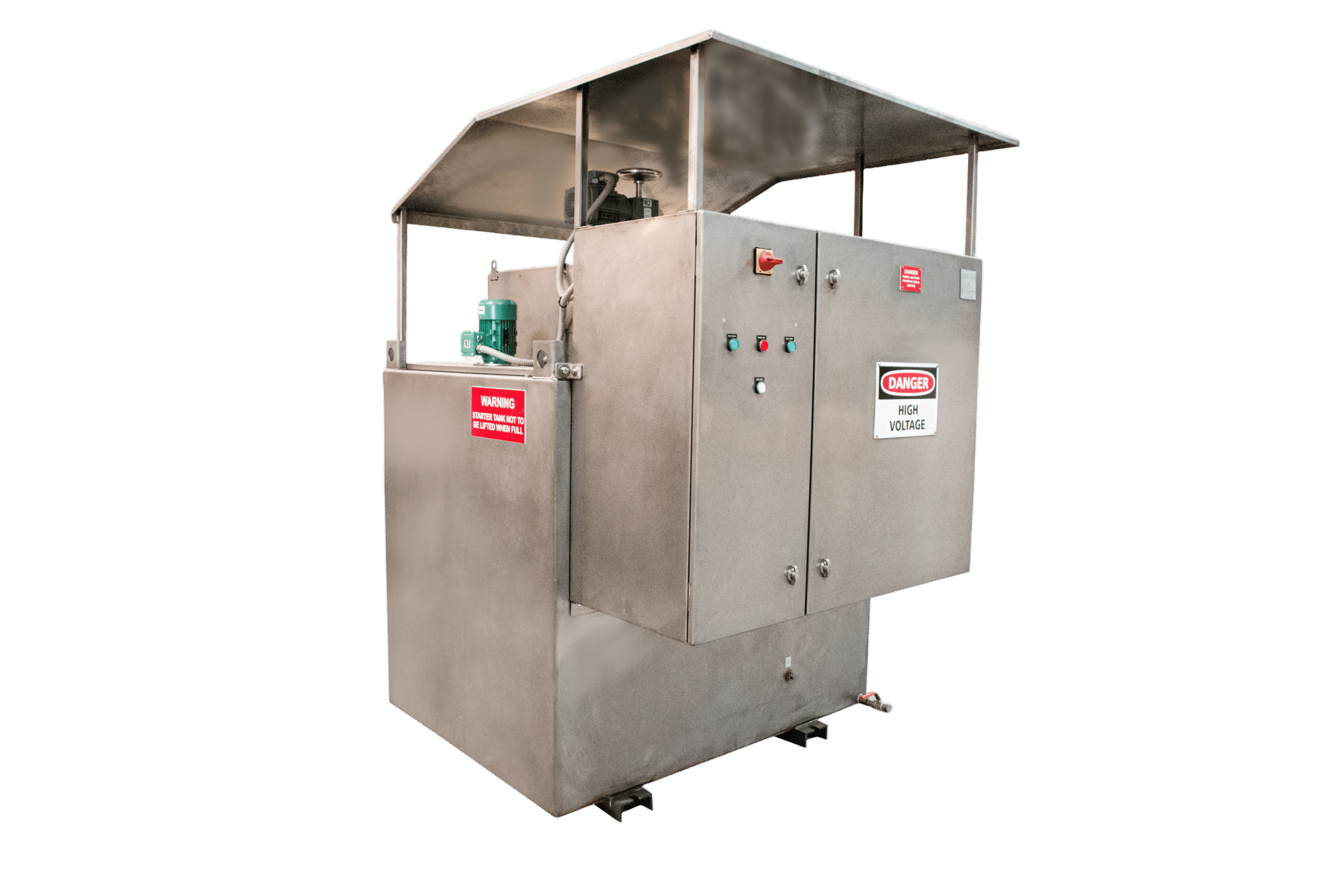

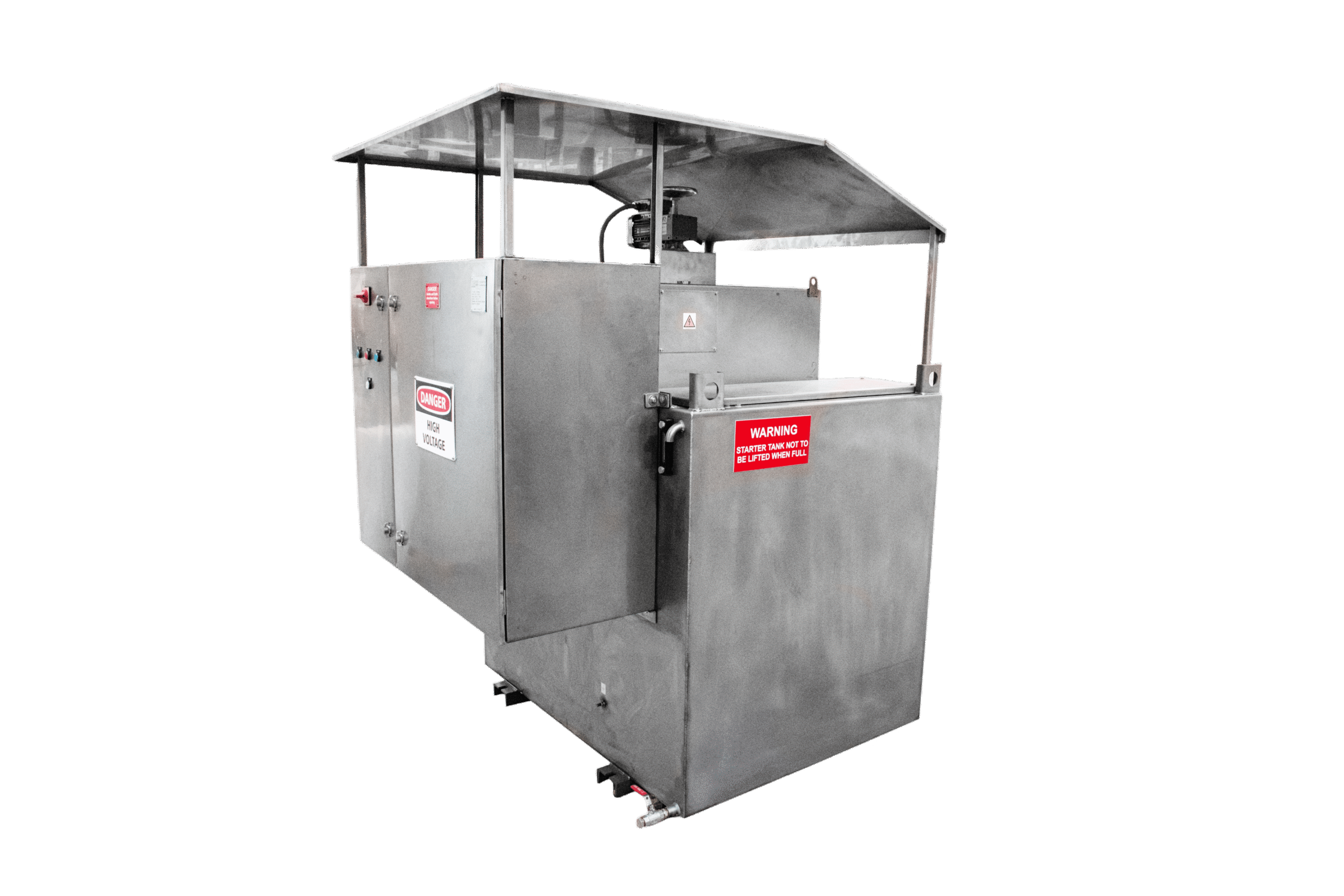

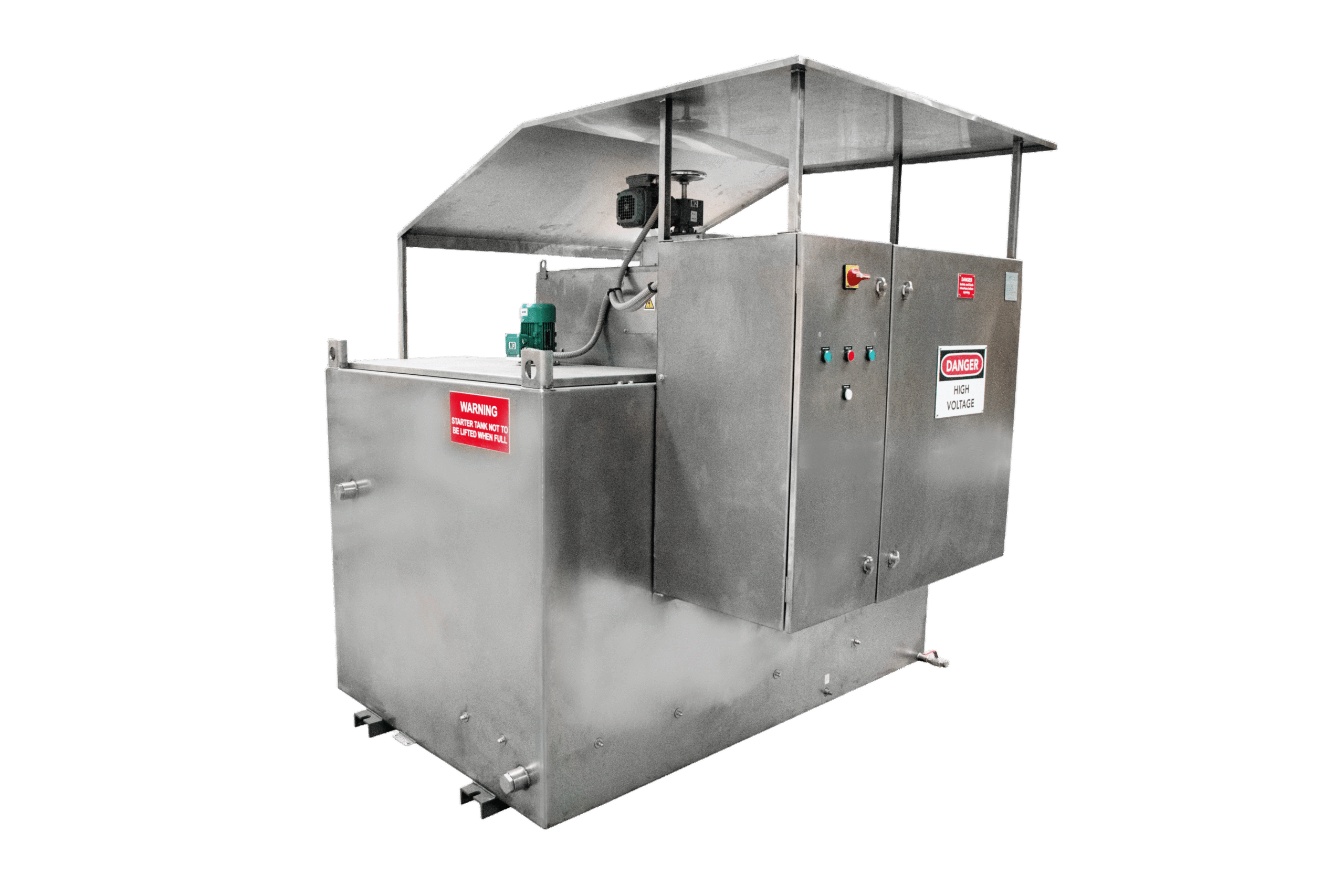

Model: Liquid Starter (Motor Starter System)

Type: Liquid Resistance Starter

Brand: Gino-AKA (France)

Models: AL, MAK, SKS, Compact

Motor Range: Up to 15MW

Voltage: 400V – 11kV (customisable)

Resistance Medium: Electrolytic solution

Electrode Travel: Vertical or horizontal

Electrode Material: Bronze alloy or stainless steel

Cooling: Natural or forced circulation

Construction: Enclosure and tank in mild steel or stainless steel

Control: Manual or automatic ramp sequencing

Model: Oil Cooled Starter (OCS)

Type: Oil Cooled Starter (OCS)

Brand: Gino-ESE (Germany)

Model: 3PA3

Motor Range: Up to 12.8MW

Voltage: Up to 5kV (customisable)

Resistance Medium: Mineral-based insulating oil (VDE 0370-2:2013-11, DIN EN 60296:2012-12, or IEC 60422:2013)

Construction: Mild steel or stainless steel enclosure and tank

Control: Cast iron resistor elements and power contactors

Model: Motor Monitoring (AKAMAS)

Type: Motor Monitoring System

Brand: Gino-AKA (France)

Model: AKAMAS 2.0

Connectivity: USB, Ethernet, Wi-Fi

Interface: Integrated touchscreen display

Data Logging: Custom Gino-AKA software (PC-based or remote access)

Details

Use Case: Motor Torque Control

Rotor resistance starter systems are used where precise torque management during motor start-up is critical. A common application is long-distance conveyors in mining environments, where uncontrolled torque can damage equipment or cause operational delays.

The Fortress Approach

Every Fortress Motor Starter Cabinet is engineered, built, and tested to meet the demands of the specific site and application. We design using corrosion-resistant resistor elements and tailor each enclosure to site conditions and customer specifications. Our designs follow applicable AS/NZS, IEC, and IEEE standards to ensure safety, reliability, and long-term performance.

System Flexibility

Whether for new projects or upgrade works, Fortress offers fully integrated RRC systems, standalone resistor banks, or control-enclosure combinations. We work closely with site teams to match SCADA protocols, PLC brands, and control layouts to simplify commissioning and integration.

We’re here to answer all your questions

Got questions? We’ve got answers! Below are some of the most common inquiries about our products and services. If you don’t find what you’re looking for, feel free to reach out to our team—we’re happy to help!

Yes. Fortress supplies spare and replacement resistor banks in IP00 configuration as required.

We prefer torque curves to be provided, but if unavailable, Fortress can work with you to develop a suitable model based on motor data and application.

Yes. We can supply control systems using your preferred PLC brand to ensure full SCADA compatibility.

Resistor elements are designed in accordance with IEEE C57.32a (temperature rise) and IEC 60071 (insulation). Control panels follow AS/NZS 3000, AS/NZS 61439, AS/NZS 2081, and customer-specific standards.

To quote accurately, please provide the motor power, stator and rotor voltage, rotor current, torque profile, number of required consecutive starts, time between starts, and any control system specifications.